Safran Cabin Lamphun Ltd.

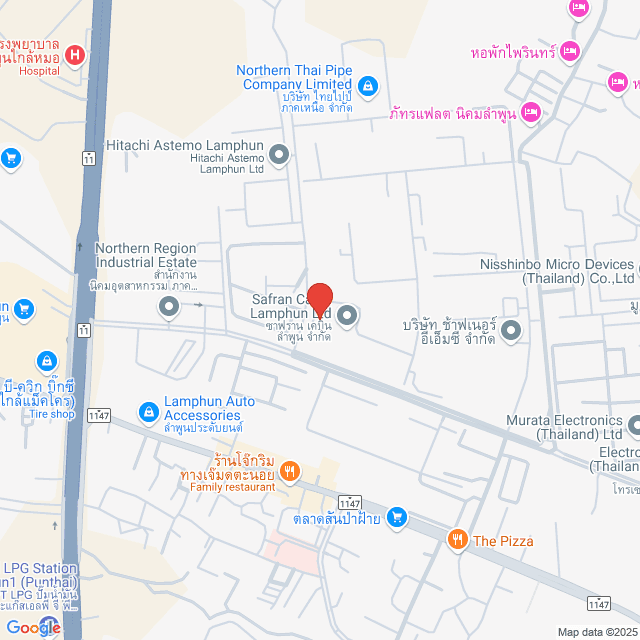

Safran Cabin Lamphun Ltd.The Group operates in Thailand through the Safran Cabin site located in Lamphun, Northern Thailand. The manufacturing site specializes in electrical inserts such as espresso makers, microwave, convection and combi ovens, chillers and trash compactors.In addition, the Lamphun site is a preferred metal manufacturing location for Safran‘s other businesses. The facility delivers full turnkey processed metal and plastics for its internal customers, and is AS9100 certified.SAFRAN CABIN LAMPHUN is part of the SAFRAN Group in Paris, France and has been operating in Lamphun, Thailand.To find out more about the SAFRAN Group:https://www.safran-group.comProduction Engineer

Safran Cabin Lamphun Ltd.Basic Requirements Full Time2 - 5 YearNorthBachelor's DegreeNegotiableResponsibilities

- Drive activities to increase CNC-MGA efficiency (Material, Yield, Scrap Reduction, Labor/Machine Efficiency) in accordance with CNC production task schedule.

- Optimizes the manufacturing system of existing products in the plant.

- Cooperates with the Engineering and Manufacturing Engineer Team to support the industrialization of new items.

- Establish manufacturing documentation and release manufacturing process documents.

- Issue process flowcharts.

- Establish and maintain the plant lay out.

- Defines and manage the procurement of production supply, small equipment and material handling means necessary for production.

- Maintain and optimize the serial production routing times (using estimation methods before production or time measurements in production).

- Coordinates Engineering Changes in the shop floor process.

- Design jig and tool for fool-proved protection of human error in process.

- Supports “Problem Solving”, Corrective & Preventive action related to customer complaints.

- Participate in Failure Mode and Effects Analysis (FMEA) process analysis.

- Stimulate Production team for continuous improvement and drives process improvement workshop. Improves process control to manufacture defect free products.

- Continuous improvement by concept of LEAN manufacturing.

- Integrate safety and ergonomics principles in process design.

Requirements

- Completed education of not below Bachelor Degree in Mechanical Engineering, ,Electrical Engineer, Industrial Engineering or any related field.

- 2-3 years of metal manufacturing process as a minimum.

- Team player with strong written and oral communication skills

- Good knowledge of milling process with CNC machines and/or manufacturing sheet metal parts (folding, welding, chemical treatment, assembly).

- Having basic knowledge of SOLID WORKS and/or AUTOCAD.

- Knowledge of lean manufacturing tools and their implementation is an advantage.

- Good command of both spoken and written English.

- Respect teamwork.

Welfare and Benefits

- Diligence Allowance

- Life Insurance

- Meal Allowance

- gasoline allowance

- Provident Fund

- 5-day work week

- Social security

- Health insurance

Other interesting jobsTags:Find jobsApply jobsSafran Cabin Lamphun Ltd. jobsEngineering jobsAutomobile & Parts jobsChiangmai jobsChiangrai jobsKampaengphet jobsLampang jobsLamphun jobsMaehongson jobsNakhonsawan jobsNan jobsPetchabun jobsPhayao jobsPhicit jobsPhitsanulok jobsPhrae jobsSukhothai jobsTak jobsUthaithani jobsUttaradit jobsCnc Machining jobsMachine jobsMilling Machine jobsCompany reviews about ‘Good Life Good Work Good Pay Good Community’

Employee reviews scoreFrom 8 Reviews 5

Dream CompanyFinestGood Life4.6Good Work4.1Good Pay3.5Good Society4.2Employee reviewsAdministration>1 years, former5.0Good Life5Good Work5Good Pay5Good Society5สวัสดิการดี29/08/2023Read all reviews ofSafran Cabin Lamphun Ltd.